1. Hana ʻia nā magnet neodymium mai ka pauka o ka neodymium, ka hao, a me ka boron i hui pū ʻia ma lalo o ka wela kiʻekiʻe a me ke kaomi e hana i ka huahana i hoʻopau ʻia.

2. Hoʻokomo ʻia ka hui ʻana o ka pauka i loko o kahi pahu a i ʻole pahu a hoʻomehana ʻia i kahi mahana kiʻekiʻe i hoʻomaka ai e hoʻoheheʻe a hui.

3. Ke hiki aku ka mea i kona wahi hehee, paa ia ma keia mehana no kekahi manawa a hiki i ka paa ana i hookahi apana me ka ole o na hakahaka a mawae paha mawaena o na mea liilii.

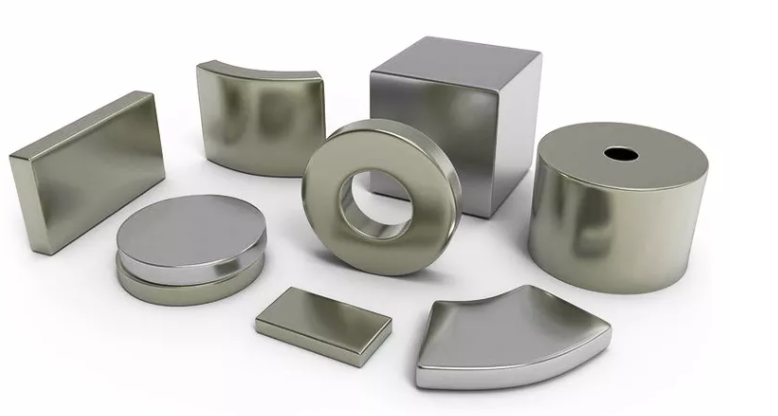

4. Ma hope o ka paʻa ʻana o ka paʻa, hiki ke hoʻohana ʻia ka magnet i kona ʻano a me ka nui i makemake ʻia me ka hoʻohana ʻana i nā mea ʻoki like ʻole e like me nā mīkini wili a i ʻole ka lathe ma muli o nā kikoʻī noi.

5. Hiki ke ho'oma'ema'e 'ia nā 'ao'ao o ka magnet inā makemake 'ia ma mua o ka uhi 'ia me ka nickel a i 'ole ka zinc no ka pale 'ana i ka corrosion.

E ʻoluʻolu e ʻoluʻolu e ʻike i ka pakuhi kahe ma lalo nei:

| ʻAʻole. | Kaʻina Hana | Hana Hana | Hana ʻenehana |

| 1 | Nānā Mea Maka | 1.ICP-2.Kemeka-3.Analyser(C&S) | ʻIke ʻia ʻo Rohs Ho'āʻo Hoʻohui Hoʻomaʻemaʻe ʻana |

| 2 | Lapaʻau mua ʻana i nā mea maka | 4. Kaʻili- 5. Hoʻomaloʻo- 6. Hoʻomaʻemaʻe Impact | Hao ʻili Ea Hoomaloo Hoomaemae Impa |

| 3 | Hoʻomalu Mea | 7.Ingredient Mana | Weigh Batching Hoʻohui i nā mea maka |

| 4 | Hoʻolei ʻana | 8. Hoʻoheheʻe-9. Hoʻoheheʻe-10. Hoʻolei | Hoʻomāmā hehee Hoʻoheheʻe Ke hoolei ana |

| 5 | Hoʻoemi Hydrogen | 11.Pre-treating-12.Vacuumizing-13.Add Hydrogen | Hana mua Hoʻomāmā Hoʻopau ʻia e ka Hydrogen |

| 6 | Milling | 14.Shattering-15.Grinding-16.Jet Mill-17.Granularity Control | Nahaha wili Jet Mill Ana Rogular |

| 7 | Ke kaomi ʻana | 18. Paona pauda -19. Pa'i mua - 20. Pa'i -21. kaomi isostatic | ʻO ke kaupaona pauda Paʻi mua Ke kaomi ʻana kaomi isostatic |

| 8 | Hoʻopaʻa ʻana | 22.Vacuumizing- 23.Sintering -24 Heat lapaʻau | Hoʻomāmā Hoʻopaʻa ʻana Hoʻoponopono wela |

| 9 | Nānā | 25.BH kaha-26. PCT-27. Ho'āʻo Density -28.Roughcast Inspection | Ana mākēneki Ho'āʻo hoʻohālikelike wela PCT Ana Paʻa Nānā |

| 10 | Mīkini | 29.Grinding -30.Wire cutting-31.Inner blade oki | wili ʻoki uwea ʻOki ʻoki i loko |

| 11 | QC hōʻike hōʻike | 32.QC hāpana ho'āʻo | QC hōʻike hōʻike |

| 12 | Chamfering | 33. Hoʻopiʻi | Chamfering |

| 13 | Electroplating | 34. Electroplating Zn 35. Electroplating NICUNI 36. Phosphating 37. Chemical Ni | Electroplating Zn Electroplating NICUNI Phosphating a i ʻole Chemical Ni |

| 14 | Nānā i ka uhi | 38. Mānoanoa-39. Kū'ē Kū'ē -40. Adhesiveness-41.-Ka hoʻomanawanui Inspection | mānoanoa Pale ʻino Hoʻopili Nānā Hoʻomanawanui |

| 15 | Mākēneki | 42. Hoʻopiha piha- 43. Mākaʻikaʻi- 44. Arraying / Involution- 45. Magnetizing | Nānā piha Hoailona ʻO ka hoʻonohonoho ʻana/involution Mākēneki Ho'āʻo Magnetic Fiux |

| 16 | Hoʻopili | 46. Puka Mane- 47. Bagging- 48. Hoopa'i | ʻeke ʻeke Hoʻopili |

Ka manawa hoʻouna: Feb-15-2023